Repair, Restoration, Overhaul, Appliances

STEAM LOCOMOTIVES

Steam Locomotive Restoration, Repair and Operations Services

From traditional steam locomotive restoration to innovative rebuilding (including efficiency-increasing measures such as installation of feedwater heaters, stokers, and fuel conversions), FMW can handle any steam locomotive project as your contractor, project manager, or consultant. FMW is also ASME-S and NIBC-R certified for the repair and construction of locomotive and traction boilers.

Restoration and Overhaul

The principals of FMW have overseen the restoration to operation of multiple steam locomotives. Our team of experts can serve in varying capacities, from acting as contractors overseeing every aspect of a restoration to working alongside client’s staff and volunteers to manage and guide the overhaul. We employ standard practices from the steam era, updated with best practices of today’s railroading, to return engines to operation.

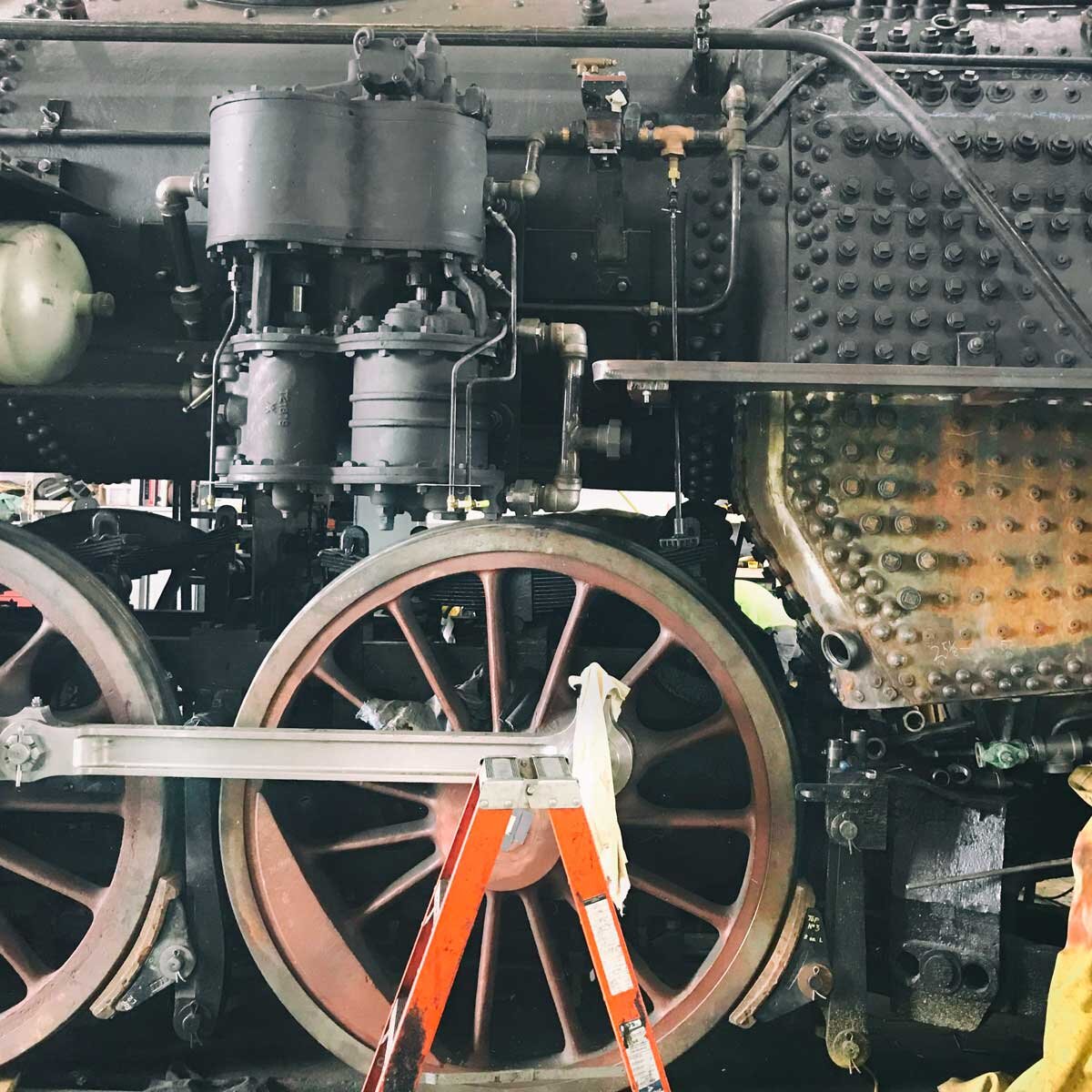

Running Gear Repair

The power of a steam locomotive is derived from its driving and running gear, and ensuring the engine is in tram and maintained to proper tolerances is key to ensuring an efficiently-operated steam engine. Our team has overseen the repair, modification, and rebuilding of running / driving gear of multiple steam engines, ranging in size from 2-8-0s to 4-8-4s. We have also fabricated driving boxes from scratch and converted engines from grease cake to force fed oil lubrication with spring pad lubricators.

Locomotive Boiler Repair

FMW solutions is accomplished in all facets of steam locomotive boiler making and repairs. Our qualified welders, fabricators, and boilermakers are experienced in the following key aspects of locomotive boiler repair: 1) sheet flanging; 2) staybolt installation; 3) complete firebox rebuilding; 4) stoker installation; 5) oil firing equipment installation; 6) grate repairs; 7) weld build up; 8) rolled patch installation; 9) tube sheet fabrication and installation; 10) tube installation; 11) superheater element inspection, testing, repair, and installation; and 12) related steam locomotive boiler making services.

Locomotive Inspection and Diagnosis

We pride ourselves in the quality, and objectivity, of the work we perform on behalf of our clients, and this extends to undertaking detailed mechanical inspections of steam locomotives. Many not-for-profits and tourist railroads seek to return steam locomotives to operation, and the first step is scoping out what needs to be done to return it to operation. FMW provides all manner of steam engine diagnostic inspection and repair services.

Steam Locomotive Appliance Repair

FMW is experienced in the repair of every type of appliance commonly found on steam locomotives. This experience includes, but is not limited to: 1) single stage and cross compound air pumps; 2) feed water heater systems; 3) dynamos; 4) oil burning equipment; 5) stokers; 6) throttles; 7) fire doors; 8) blow down valves and systems; 9) pop valves; 10) multiple unit (MU) diesel locomotive control systems; 11) bearing box temp sensors; and 12) related services.

Wheel Work

FMW is experienced in the inspection, repair, and overhaul of steam locomotive driving wheels. FMW is experienced in providing the following locomotive driving wheel services: 1) tire re-profiling; 2) wheel center crack repair and renewal; 3) journal and hub re-facing; 4) axle replacement; 5) conversion to roller bearings (lead and trailing axles); 6) crankpin quartering; and 7) related steam locomotive wheel repair services.

A picture is worth 1,000 words...

...and we believe those images included on this site speak volumes. Our Team has been involved in the successful restoration, operation, and maintenance of over a dozen steam locomotives, ranging in size from 2-8-0s to mainline 4-8-4s, in the United States and England. We pride ourselves on the quality of our work and the combination of historical practices with state-of-the-art materials, technologies, and techniques. Should you want to learn more, please feel free to drop us a line.